The importance of cell monitoring

Every battery is made up of cells with plates connected in parallel to obtain a certain capacity (amp hours), and those groups of parallel plates or cells are connected in series to build voltage.

If you could pull apart any dead battery, no matter what type, the internal cells would be out of balance to some degree, but this doesn't necessarily mean each of the internal cells are dead. The highest voltage cell, or the one with the most capacity loss, will get over charged if it is ahead of the other cells. The same happens on discharge, but the low cell will be damaged. In a flooded cell lead acid battery, the high voltage cell will bubble away and need more water. With a sealed AGM or gel lead acid battery, the bubbling of the electrolyte will cause overheating and - in the case of the gel battery - serious and irreversible damage.

The same is true of a lithium battery - any cell which is over voltage will result in damage, which in turn will cause the failure of the entire battery.

There's not a lot you can do about an off-the-shelf battery, whether it's lead acid or lithium, because to measure the voltage of each cell in the battery you would have to open the case and therefore void your warranty.

Look after the cell voltages and the battery voltage will look after itself

At T1 Lithium we build our batteries out of cells for the very reason that by monitoring the cells of our batteries and keeping them within safe voltage limits, the battery itself is, by default, protected from damage. We strap these cells together and we protect the terminals with a cover, but we do not hide the cells in a box. It is not at all hard to balance cells, and we provide the charger and detailed instructions on how to do this should the need ever arise. This is why we have customers into their 9th year of their T1 Lithium system, many in full-time use.

Safe lithium voltages

As long as there are some lithium ions left in the lithium compound that coats the positive plate and somewhere for them to link into the graphite coating on the negative plate, there are no secondary reactions in a LiFePO4 cell, as long as the cell voltage stays within the safe range, the battery as a whole will by default stay within the safe voltage range.

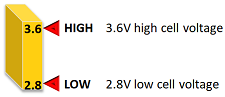

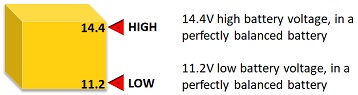

For lithium ferrous cells (LiFePO4 and LiYFePO4), this safe range is:

Safe cell voltage

Safe battery voltage (provided all the cells are between the safe voltage levels)

Why is monitoring cell voltage so important?

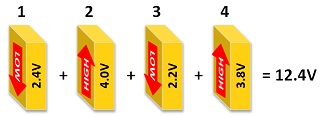

There are a lot of combinations of 4 cell voltages that can make up a battery voltage somewhere between the 11.2V low and 14.4V high. In the example below, cells 1 and 3 are both too low, and cells 2 and 4 are both too high. Yet the total battery voltage is 12.4V, which is well within low and high battery voltage limits. Yet every cell in the example below is dying, either from over charge, or over discharge.

The difference between zero volts and zero percent state of charge

There is a common misconception that a "flat battery" means there is no voltage left in that battery. This is not the case.

In a properly capacity-rated lithium battery, when we talk about 100% state of charge, we mean 100% of the advertised capacity, or remaining capacity of each cell of the battery. So, if you use 100% of the capacity of a 100Ah battery, you have used 100Ah.

In a T1 Lithium battery, you have NOT drained the battery to zero voltage, or even drained a cell to the 2.8V that signifies a low cell voltage. We know this because we monitor every cell in the battery.

High cell voltage in a lithium cell is only seen in the last 0.5% of charging, in other words, when the cell reaches between 99.5% and 100% state of charge (SOC). Low cell voltage in a lithium cell is only seen when 100% of the capacity has been drained. This can be more than 100% of the advertised capacity, or below 0% state of charge.

Even in a lead acid battery, at 0% SOC, there will still be around 1.75V per cell in a balanced battery.

The fact that in a lithium battery, damaging low or high cell voltage only happens at the extremes of discharging or charging is pertinent when we look at internal cell balancing within a lithium battery. So, let's take a look at cell balancing...

Built-in cell balancing

Some sealed lithium batteries rely on cell balancing to ensure that each lithium cell, and therefore the battery as a whole, is within safe voltage limits. Cell balancing works by taking excess capacity from one cell and moving it to another cell of lower capacity. The balancer can only sense voltage, so a higher voltage is seen as a higher capacity.

The fact that the serious out of balance voltage in a lithium cell is only seen when a cell is at about 99.5% fully charged or at or below 0% SOC, to use cell balancing using cell voltage as the trigger means either the full charging amp or load amp have to removed out or into the affected cell.

A good cell balancer can move about 0.5 amps (ie; 0.5 of an amp hour, per hour). A cheap cell balancer can move around 0.05 amps. A really good active cell balancer can move 1 amp, or even 1.5 amps in a very out of (voltage) balance battery.

Because the charge current could be as high as 100 amps or more (where multiple charging devices are operating at the same time), it would be impossible for any balancing device alone to protect the cell from over voltage damage. Even if the only charge was coming from a small solar array, there are still way more amps that need to be diverted by a balancer than it is capable of moving at only 1 amp at best.

Let's look at the load side. Because the load can be much higher and the balancer cannot move enough from the other cells into the low cell, that cell gets dragged down to zero volts. If the other cell voltages from those in series are also low enough, then the battery voltage will drop low enough for the load cut to trip.

Unfortunately, if the cell voltages are high enough to meet the 10.5V cut off often used by many inverters and drop-in battery builders (10.5 ÷ 3.5V in the other 3 cells), now the cell with zero voltage can't add anything to the total current, but the other cells can, so the current from the other cells is forced through the zero volt cell causing a reverse current flow, the current and voltage at the (-) terminal becomes higher than the current and voltage at the (+) terminal.

This reverse current flow is a killer for lithium cells, because the lithium itself is separated from the compound and plated on the separator and graphite coating on the other plate. This lithium cannot be recombined into the LYP mix and not only is part of the active material lost (loss of capacity), but this lithium metal will build up enough to create a bridge between the lithium coated plate and the graphite coated plate and this bridge short circuits the cell. It can never be recharged.

Our cell monitoring

Firstly, we monitor the voltage of each cell in a battery. Remember that we build one single battery of the size required, so regardless of how large or small one of our batteries is, in the 12-volt system there are always only 4 cells to monitor (in a 24-volt system there are 8).

So yes, we monitor the voltage of the battery, but more importantly, we monitor each individual cell. We also show the voltage differential, which is the difference in voltage between the lowest cell and the highest cell. Our control system stops charging at high cell voltage or isolates the battery at low cell voltage to stop discharging.

Why do our cells stay generally in balance?

The all-important part of the process we employ to build a lithium battery from 3.2V lithium cells is in how we condition charge each battery as part of its very first charge. This is something that we learnt and refined in our very early days. Sorry, we're not prepared to share how that is done.

Cell balancing

In a closed-lid battery, you don't get to see the cells that make up that battery, so even if you knew the cells were out of balance, there is nothing you could do about it.

This is an integral difference between a swealed system and a T1 Lithium battery. We give you the means and the instructions (it's quite a simple process) to bring up the voltage of a low cell, should it become necessary. It doesn't happen often, but we see no reason why your entire battery should die because you're unable to fix a simple problem.

Do you need a full-time balancer?

If a 12V battery is built using 4 cells in series, the answer is no. A full-time active balancer on its own can actually be detrimental to the battery health.

Don't confuse battery monitoring with battery management. Our system monitors, warns if the battery gets low and automatically isolates the battery if you aren't there to hear the alarm.